Eighteen months after investing in a “cutting-edge” control system, a facilities director at a prominent UK university was shocked to find a 23% rise in energy bills. The anticipated savings? Nowhere to be found. Instead: rising maintenance costs, ongoing user complaints, and the growing realisation that their smart building was quietly leaking money.

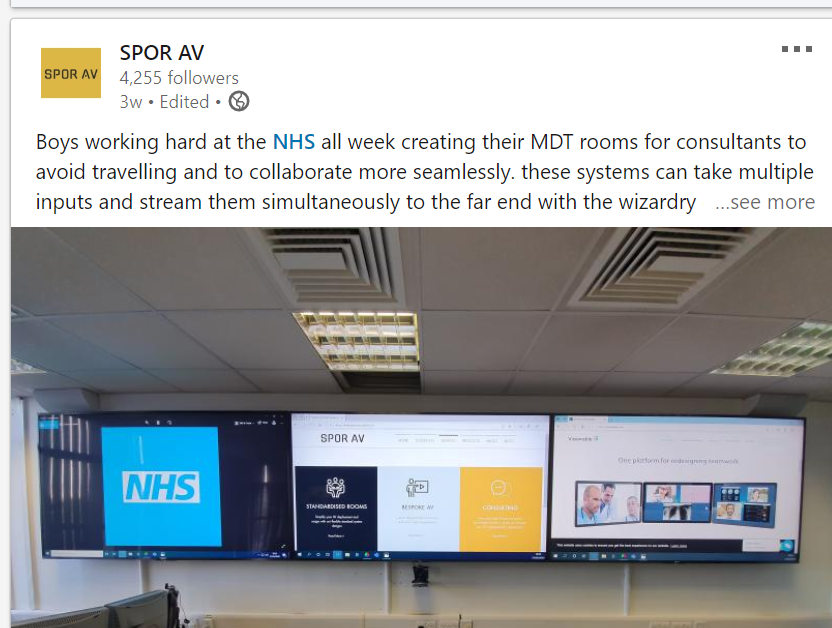

Across the UK and Europe, this scenario is alarmingly common. From corporate headquarters in Frankfurt to NHS trusts and university campuses, control systems intended to save money often do the opposite—simply due to flawed implementation and neglected optimisation.

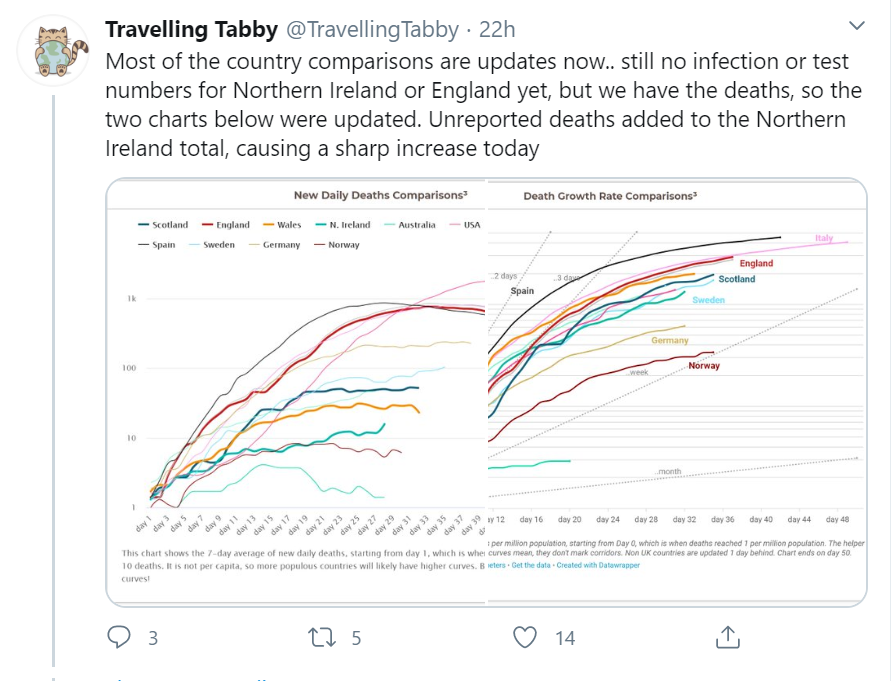

A recent review of 200+ commercial buildings across Europe found over 65% of control systems operating inefficiently, wasting £2,000–£5,000 per month—or up to £60,000 per year. That’s the equivalent of a full-time salary or several capital improvement projects lost to invisible inefficiencies.

The Technology vs. the Reality

Modern control systems form the digital backbone of smart buildings—regulating HVAC, lighting, AV, and security systems. Done right, they offer energy savings of 15–30%, improved comfort, and longer asset life.

But in practice, many fail to deliver. According to CIBSE (Chartered Institution of Building Services Engineers), a majority of facilities managers report performance falling short of design intent—not due to the technology itself, but how it’s commissioned, integrated, and maintained.

Let’s explore five of the most costly—and fixable—control system mistakes draining budgets across the UK and Europe.

Mistake #1: Disconnected Systems Working at Cross-Purposes

Many facilities evolve over time, layering in separate systems from different vendors—lighting from one, HVAC from another, AV from a third. The result? Systems that operate in silos, often conflicting with each other.

At a London-based office complex, occupancy sensors dimmed lighting to save energy. But the HVAC system, running on fixed schedules, continued heating unoccupied spaces. The result: comfort issues, staff complaints, and an estimated £35,000 in wasted energy annually.

Fragmented systems also lead to duplicated work, with facilities teams spending hours manually coordinating or overriding systems. In this case, the FM team reported an extra 10 hours per week, amounting to £15,000 in labour costs per year.

And without unified data, it’s impossible to see how the building is performing overall—blocking long-term efficiency improvements.

Mistake #2: Interfaces That Intimidate Rather Than Empower

Even the best technology fails if users can’t (or won’t) use it properly.

After a university in Manchester rolled out a £1 million classroom AV upgrade, over 70% of lecturers avoided using the new features—citing confusing controls and inconsistent interfaces. They used only the basics, leaving most of the system’s capability untapped.

Poor UX leads to three major costs:

- Wasted investment: Surveys show only 40% of system features are typically used—so on a £200,000 system, that’s £120,000 of unrealised potential.

- Lost productivity: At a European financial services firm, executives spent an average of 6 minutes per meeting troubleshooting room systems—adding up to £60,000+ in lost staff time annually.

- Energy waste: At a Belgian college, 40% of rooms were found to have equipment left on overnight due to complex shutdown procedures—costing €30,000 per year in unnecessary energy usage.

Mistake #3: Skipping Proper Commissioning and Ongoing Optimisation

Far too many control systems are treated as “install and forget” technology. Without proper commissioning—and ongoing fine-tuning—systems fall out of sync with real-world building use.

At a major German hospital, an audit two years after installation revealed 50% of temperature sensors were inaccurate, and VAV systems were running in override mode due to initial programming errors. The facility was using 18% more energy than necessary—an annual cost of €150,000.

Neglecting commissioning also shortens system lifespan. According to REHVA (the Federation of European Heating and Ventilation Associations), improperly maintained control systems experience up to 30% higher failure rates. For a large commercial building, that could mean £40,000–£50,000 in extra maintenance costs per year.

And the longer systems go without optimisation, the further they drift from actual occupancy patterns—leading to persistent waste.

Mistake #4: Underpowered Networks and Weak Cybersecurity

Modern control systems rely on IT infrastructure, yet many buildings still connect them via legacy networks—creating bottlenecks and vulnerabilities.

A school in Bristol experienced system-wide AV failure during a public event because their control system shared bandwidth with administrative systems. The last-minute fix—including equipment hire and staff overtime—cost £10,000 for a single event.

Downtime from overloaded networks costs more than inconvenience. In commercial buildings, each hour of system failure can translate to £0.20–£0.35 per square foot in productivity losses. For a 75,000-square-foot office, that’s £15,000–£26,000 per hour.

Cybersecurity is an even bigger concern. Building control systems are often poorly secured—despite being an ideal back door for hackers. In 2023, a Scandinavian logistics firm suffered a €400,000 ransomware attack after hackers entered via unpatched HVAC controllers.

Mistake #5: No Plan for Lifecycle Management

Unlike mechanical equipment, control technology ages fast. Core components and software may become unsupported in as little as five years—yet many facilities plan for 15+ year usage cycles.

Central Europe University faced this challenge after neglecting updates for six years. When a critical system failed, they found key components discontinued and integration impossible. The emergency replacement cost €1.5 million—over 40% more than a planned upgrade would have.

Compare that to a proactive strategy. A corporate park in the Netherlands follows a five-year refresh plan, budgeting 10–12% of the original system cost annually for maintenance and upgrades. Their total cost of ownership is 25% lower over 10 years than peers using reactive models.

Turning Waste Into Advantage

Correcting these five mistakes can free up £100,000–£200,000 annually for a mid-sized UK or European facility. More importantly, it turns control systems from a hidden liability into a performance asset.

Step one: conduct a full system audit. Assess integration, UX, commissioning, network readiness, and lifecycle status. Most buildings will uncover immediate savings.

Step two: pursue integration. Often, middleware or cloud-based solutions can unify legacy systems without full replacement—delivering 70% of the benefit for 30% of the cost.

Step three: redesign interfaces around real users. Involve end users early. Modern, intuitive UIs often pay for themselves within a year.

Step four: implement continuous commissioning. Ongoing tuning typically saves 10–15% in energy and improves occupant satisfaction—often with guaranteed payback through performance contracts.

Step five: secure your infrastructure. Use dedicated networks and update cybersecurity protocols. These protections are not optional—they’re insurance against reputational and financial disaster.

Finally: plan for obsolescence. Recognise that control tech evolves quickly. Annual budgets should include not just break/fix costs but future-proofing.

Why Expertise Matters

Success lies at the intersection of AV, IT, building services, and human behaviour. Most project teams don’t cover all those bases.

That’s why organisations like LCD have emerged as leaders across the UK and Europe. By combining engineering, IT, and UX with real-world operational insight, LCD helps clients unlock true ROI from their systems.

Their CTO summarises it well: “The technology didn’t need replacing—our implementation approach did.