Aims

This short document aims to present the common Lighting Control System Standards used in the lighting industry today and give a short explanation of their development, uses, advantages and disadvantages.

Introduction:

Lighting can be switched on or of and it can be dimmed that is the light output of the lighting source varied to different levels in between off (no light ) and full on ( the maximum light output of the source)

Electrical Dimming

When halogen lighting is in use the dimming is simple and can be carried out either remotely or locally. A dimmer of this type (for a halogen load) achieves the dimming by reducing or increasing the level of the r.m.s. voltage and hence the average power.

Traditional Triac or thyristor dimmers use switching techniques to achieve this varying voltage. Inductors are the other main component of the dimming circuit and these are used to suppress interference caused by the switching. When a dimmer is at 50% they are switching the greatest voltage and the interference in the circuit is at its maximum. This is the cause of the vibration in the inductors that causes a buzz to be heard near to the dimming units. The inductors add weight to the dimmers and the suppression provided is often not sufficient to prevent the buzzing being heard on audio systems that share a closely related power supply.

Although the most simple form of dimming this type of dimming is not without it’s problems:

Low voltage lighting is now in very frequent use in projects using a wirewound or electronic transformer to provide a 12 v voltage for the lamps.

Traditional wirewound transformers provide an inductive load to the dimmer and the current of the load lags behind the voltage. Once triggered a triac requires the flow of current to the load through the device to maintain its operation. When the current falls below this threshold the device will switch off. If the current lag from an inductive load is sufficient the current flow in the circuit will not reach a sufficient level to maintain the triac and the device will turn off givingflashing and unwanted effects.

To avoid this effect the length of firing pulse on the dimmer can be varied to last long enough for the current to ‘catch up’ .

When using electronic dimmers only dimmers designed for use with a dimmer should be used although others may work they will not work for long.

Electronic Dimming

Electronic ballasts

Fluorescent and High intensity discharge lamps are frequently used in both residential and commercial projects. These use electronic ballasts to provide the supply to the lamp or lamps. Electronic ballasts usually change the frequency of the power from the standard mains (e.g., 50 Hz in uk) frequency to 20,000 Hz or higher, substantially eliminating the stroboscopic effect of flicker (100 or 120 Hz, twice the line frequency) associated with fluorescent lighting (see photosensitive epilepsy). These devices are often based on SMPS topology and allow dimming via pulse width modulation.

Generally these ballasts will be permanently connected to a mains power supply and also have one set of control connections either two or three core dependant on the type of control.

LED Electronic controllers

Led lighting is more and more popular due to the energy efficiency and the colour change possibilities without the need for filters.

LED units are however more complicated to dim than halogens. Dimming using a traditional dimmer above at best will not work and at worst will cause damage to your control gear and your dimmer.

Electronic controller specifically designed for controlling LED’s exists in both single channel devices and most commonly in three or four channel devices to accommodate colour change.

These devices provide a constant current supply to the LED and vary this supply using pulse width modulation to lower the duty cycle of the led and create a dimming effect.

These devices come in many shapes and sizes depending on what you wish to control. They also come as either integral units with LED power supplies or stand alone units which are connected in conjunction with and LED power supply.

Control either local or remote and if remote using 0-10V DC, DMXgenerally.

Cold Cathode Electronic controllers

The term Cold cathode is usually used to describe concealed lighting in coffers of cornices and is often used as an indirect up lighter. The name is in fact a description of the technology (fluorescent lighting for example is known as hot cathode). Cold cathode tubes are usually divided into two groups, those filled with Neon (red) gas and those filled with Argon (blue gas). The range of colours available is created by the use of different phosphors on the inside of the tubes which react with the ionized gases and emit the particular colour light.

Lighting Control System Standards –

0-10v DC (also described as analogue)

The most basic of these control signals is 0-10V DC (the same as is used as the basis of most Triac dimming systems!) However small electronic ballasts are always located locally to the fitting and hence the DC control pair must travel from the processor to the fitting and may be susceptible to interference.

Pros

·Simple to wire and understand

·Simple to test with simple test equipment

Cons

·Most common fault is inverted +/- wiring

·Susceptible to noise

DSI – Digital Serial Interface

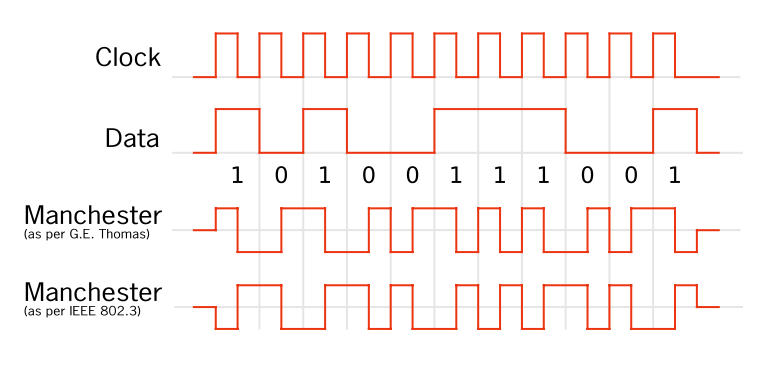

DSI is a digital protocol for controlling lighting in permanent installations. The standard uses uses a single byte to communicate the lighting level ( 0-255 or 0x00-0xFF).

In a DSI system each lantern or group of lanterns has it’s own control cable running from the processor or controller. There is no addressing of lanterns to be set.

Pros

·Simple to wire .

·Relatively simple to test with relatively simple test equipment

Cons

·Large systems have many control pairs running back to central system

·Initially a proprietary standard exclusive to Tridonic

DMX-512 –Digital Multiplex

DMX is a well know control protocol based on RS485 standard. The standard was developed for use in the entertainment industry to control multiway dimmers and intelligent lighting. Until recently the standard was never used in construction applications however due to the advent of RGB LED and cold cathode systems requiring more detailed control DMX has become the protocol of choice in these situations.

A DMX512 controller is connected to fixtures or devices in a multi-drop bus topology commonly called a “daisy chain”. 512 fixture attributes can be controlled on each DMX universe and if control of more is required additional universes can be added.

A fixture attribute may be a single channel of a dimmer.

Or a single colour on an RGB LED controller.

Fixtures are addressed using a menu structure or DIL switches. If a device has multiple fixture attributes such as a 12 channel dimmer, a 3 channel LED driver or a 32 channel intelligent light then the address of the channels first fixture will be set and the following channels will follow in sequence.

e.g. a 3 channel LED driver with starting address 1 will use

ØChannel 1 Red

ØChannel 2 Green

ØChannel 3 Blue

Channel 4 and onwards are “free” to use for other fittings.

Many devices utilize automatic addressing and while this has it’s place for certain applications I must say that from experience I am not a fan.

Pros

·Strict adherence to the daisy chain topology must be followed (no Y-splits).

·Allows very accurate control.

·Long distances are possible even without buffers.

·

Cons

·Specific shielded cable must be used CAT 5/6 is not suitable.

·Difficult to fault find at signal level

DALI – Digital addressable Lighting Interface

DALI is and open standard protocol introduced as a rival to DSI and a successor to 0-10V control systems which still dominate the industry. The protocol allows control over a number of fittings using bi-directional data exchange over single bus with a maximum of 64 devices.

Devices are addressed individually and in addition to allowing control over the device feedback is provided to the system giving status of the device.

DALI has group and scene commands as part of the protocol allowing the reduction of data traffic and reduced network latency.

Pros

·Simple to wire – It requires only a pair of wire to form the bus connecting all devices on a single DALI network.

·Relatively simple to carry out basic tests with relatively simple test equipment

·No topology restrictions STAR and T’s are OK!

Cons

·The limiting factor of 64 addresses is not enough for large installations.

·Difficult and expensive to test and fault find

·Speed of the system (1200 bits per second ) can mean visible delay in larger installations

Copyright Neil Silver Lighting Control 2007

Neil Silver is the Technical Director of Lighting Control. He carries out a wide range of design and programming work in both commercial and domestic lighting controls systems.