Automation is great and sales people sell lighting control systems based on the ability to automate tasks.

Automation is great and sales people sell lighting control systems based on the ability to automate tasks.

But as anyone who sets a daily alarm knows automation is not great when the alarm wakes you up on a Saturday morning instead of allowing you your well deserved lie in!

This is a very simple example of how automation requires a really well thought out quality specification. When setting the alarm the simple choice is to tick the “every day of the week” !

When doing lighting controls a basic automation requirement is that lights turn off automatically after all staff have left the premisis. This ensures that if lights are left on they will not stay on all night which saves on lamps and energy costs.

However on special occasions for example the christmas party the premisis is to be used after closing to host the party or on a special corporate launch night you invite your major client to a reception to lanuch your latest new product.

The presentation is then cut abruptly short as the lights dim to zero. At best this causes inconvinience and at worst can present a real health and safety problem as people are literaly left in the dark.

I remember an example of this would happen each year at our local church. The exterior of the building is floodlit by the local council controlled from a timer control located in a panel outside the church. Each Christmas the midnight service to bring in Christmas day would take place at 10:30pm and church-goers would be able to find there way around the church from the light of the floodlights. However on Christmas morning the lights would turn off at 12:30 am meaning that we would exit the church to darkness!

The simple solution has been provided in HVAC systems for many years. A three position switch on a panel allow selection of “OFF” , “ON” and “AUTO”. This allows the system to be forced off , forced on and forced to do whatever it is supposed to do depending on any automation that has been programmed into the system.

This is a really simple local overide that works and should be used as a starting point for local overide.

However our automatic specification was written to stop somebody leaving the lights on overnight. This local overide gives them exaclty this power again so we have failed to meet the specification.

Another heating control analogy is the “+1h” button or “Next Step” button often found on simple heating controllers this enables the users to slightly atler the auto mation by telling the system that for the next hour it is one hour ahead of the real time (allowing you to turn on or off the heating early) or to tell the system that for the rest iof this period of automation you want the system to do the functionality of the next period of automation.

This is better as the period of non-automation is restricted if you like the automation is automatically switched back on!

There are many methods of solving this problem and unfortunately often the problem is solved by removing the automation due to the fear of an un suspected turn off.

With good design features of lighting controls systems can be fully utilised and not hindered.

The new range of VELUX INTEGRA® skylights allow remote control via infra red for skylights above stairwells and at height.

The new range of VELUX INTEGRA® skylights allow remote control via infra red for skylights above stairwells and at height.

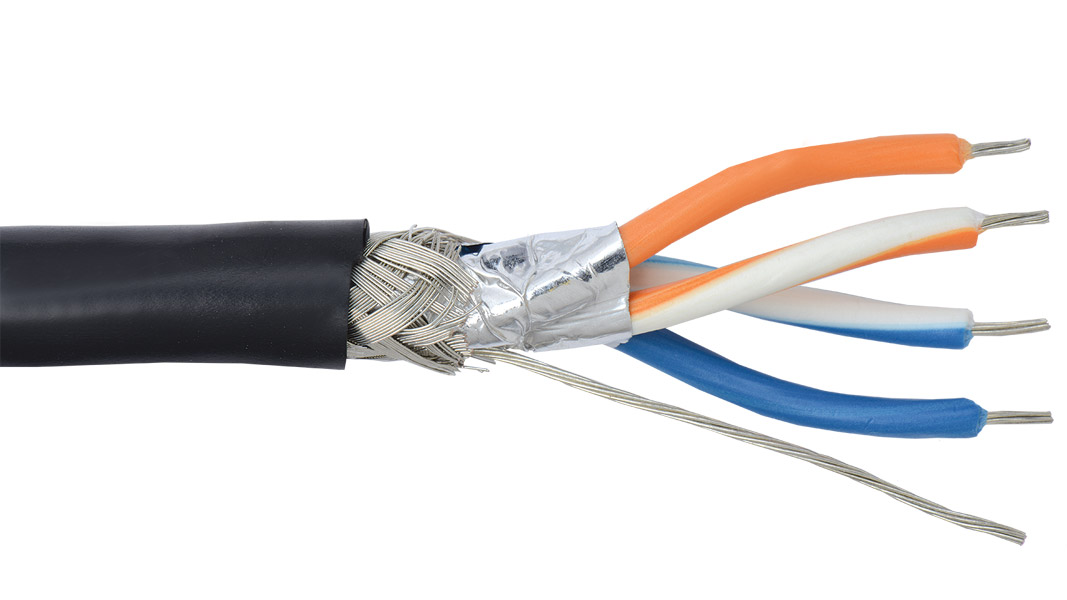

The recent introduction of the 17th edition regulations means a number of changes in the protection of circuits.

The recent introduction of the 17th edition regulations means a number of changes in the protection of circuits.